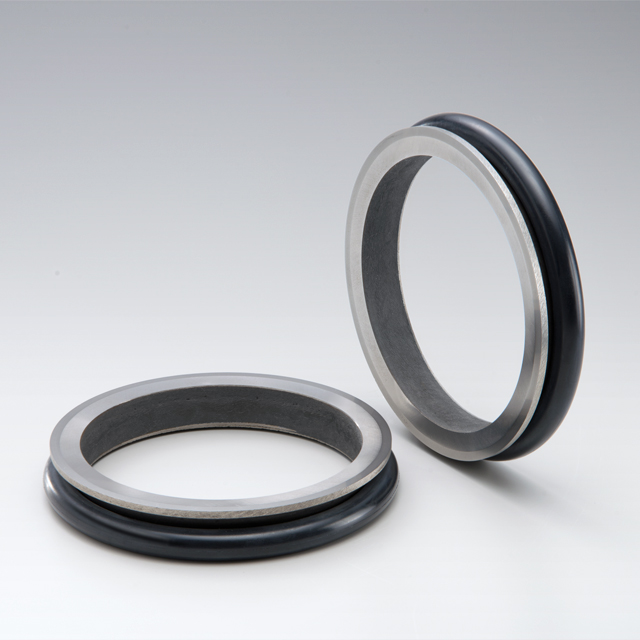

Floating Seal ES100 & ES764

Seals for undercarriages of construction machinery (track rollers, final drives, axles and idlers)

Simple structure consisting of an O-ring and a seal ring made of special cast iron

Optimum seals for undercarriages of bulldozers and hydraulic excavators frequently exposed to sand, dirt and other foreign matter

ES764 offers ease of designing and manufacturing housings.

Feature

- Floating seals are simple products, consisting of two components: a seal ring made of special cast iron and a rubber component (O-ring/gasket). In use, two identical seals make a pair. The seal ring, which is a sliding component, is not in contact with the shaft since it is sustained by the rubber component, and therefore follows the radial and thrusting motions of the shaft closely.

- Since they were developed for slurry applications, seal rings are made of an extremely hard, wear-resistant and corrosion-resistant material. The rubber component presses the seal ring’s sliding surfaces and also serves as a seal. Therefore, it is made of a material that is highly resistant to cold temperatures and heat with little compression set for a longer useful life.

- Main uses of floating seals include crawler rollers, travel drives and idlers of construction and agricultural machinery, and also for conveyors, mixers and various digging machines. In other words, they are used widely in relatively low-speed applications exposed to foreign matter.

Product specification Example

|

Sealed fluid

|

Inside: lubricant

Outside: sand, dirt and mud

|

|

Temperature

|

NBR: -40 to 100ºC

H-NBR: -30 to 130ºC

FKM: -10 to 200ºC

|

|

Maximum circumferential velocity

|

MAX. 3m/sec

|

|

Pressure

|

MAX. 0.2 MPaG

|

|

Shaft diameter

|

φ38~φ429mm

|

Note: The above figures indicate the best conditions in individual cases and may differ according to the seal size. Contact us before use.